What materials are used in the manufacturing of a body?

“Buckle up and join me on this exciting journey to explore what materials bring our vehicles to life. We’ll discuss the secrets of body manufacturing, from the strongest metals to the most sophisticated carbon fibers. A fascinating journey full of innovation, technology, and a lot, a lot of speed. Let’s get started!”

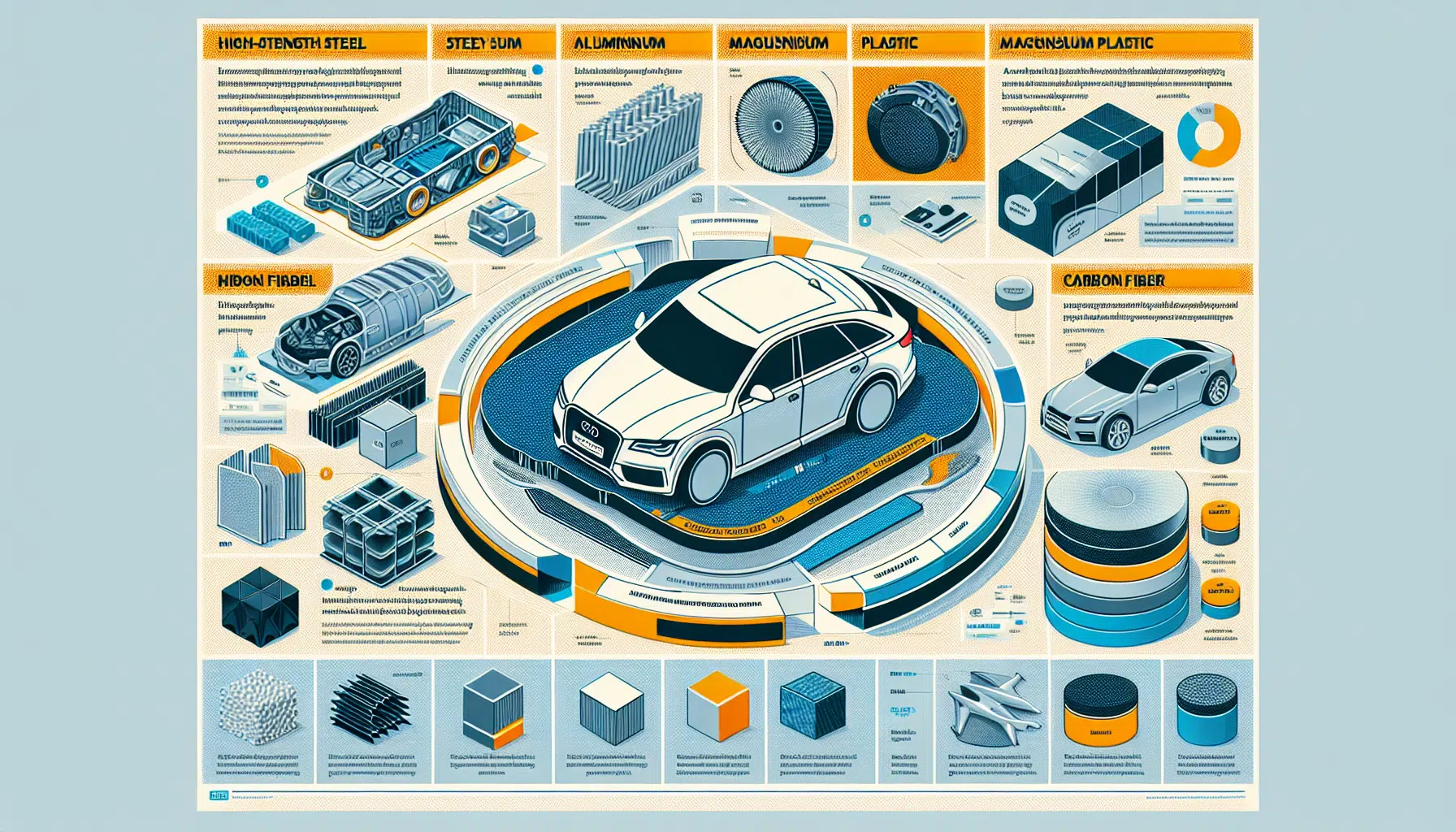

Types of materials used in body production

Body Materials: Evolution and Significance

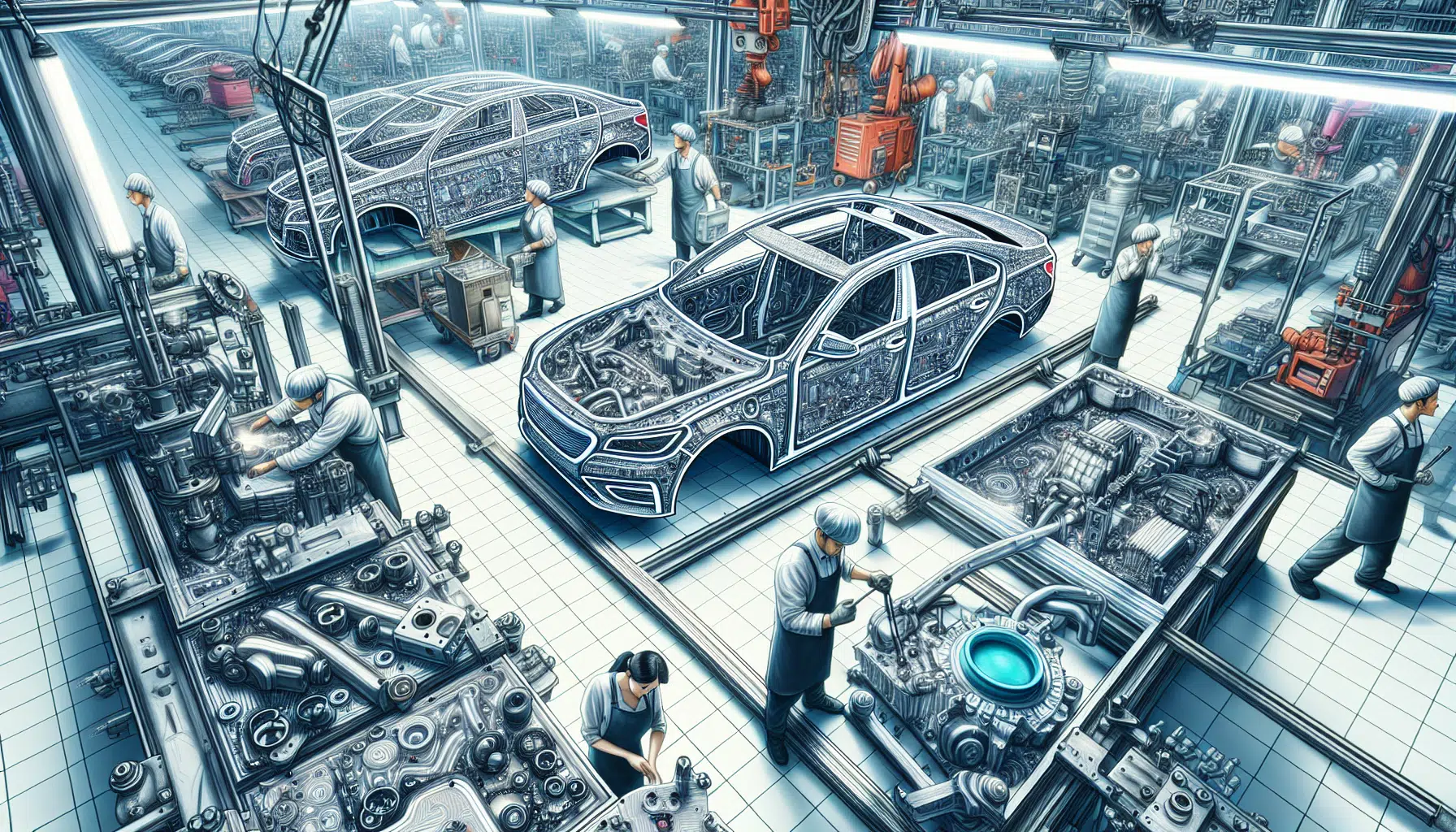

As we find ourselves immersed in the era of technology and innovation, the materials used in the manufacturing of vehicle bodies have undergone significant development. Behind every design and stylistic line, there is an engineering strategy aimed at combining strength, lightness, and sustainability.

Traditionally, automotive manufacturers have relied on steel as the preferred material for its strength and durability characteristics. But technological evolution has led to a reevaluation of this choice, resulting in experimentation and adoption of new lightweight yet robust materials.

Steel and Alloys

Steel remains one of the body materials most used in vehicle manufacturing. This long-standing material offers high strength and durability, being relatively economical and easily moldable through stamping processes. However, due to its weight, manufacturers are increasingly seeking lighter alternatives that enhance performance and fuel efficiency.

Aluminum, Lightness, and Strength

Aluminum has gained popularity among manufacturers due to its lightness and corrosion resistance, being especially relevant in the production of electric vehicles. The body of the new Audi A8 is an example of how a high-performance vehicle can be achieved using this lightweight and strong material.

Fiberglass and Carbon

With its incorporation into the automotive industry, fiberglass and carbon have revolutionized body design. Carbon fiber has incredible strength and remarkably light weight, making it a game-changer in the manufacturing of supercars and competition vehicles. BMW, for example, has heavily invested in the use of carbon fiber in its latest vehicles, seeking greater strength and lower weight.

Plastics and Composites

Plastics and composites have become an important pillar in body construction. They are lightweight, flexible, strong, and there are many different types that can be utilized in different parts of the vehicle.

The Choice of Material: Key Factors

The choice of the right material for a vehicle’s body depends on several factors, including cost, strength, lightness, impact absorption capacity, aesthetics, and increasingly, environmental impact. In the era of electric vehicles and autonomous driving, the choice of body material will continue to evolve towards lighter, stronger, and more sustainable solutions.

The Future of Body Materials

The future of body materials is filled with innovations and exciting discoveries. With every advancement in technology, automotive engineers are finding new ways to make our vehicles safer, more efficient, and environmentally friendly. In this sense, research and development in the automotive industry will continue to be the driving force behind this exciting evolution. The challenges of fuel efficiency, driver safety, and environmental concerns will continue to propel innovation in body materials.