Hydrogen engines require specific turbochargers, even more than diesel engines, and have been developed exclusively for H2-ICE engines.

In the world of automotive technology, sustainable propulsion innovation continues to gain prominence. Hydrogen engines, a promising alternative to fossil fuels, require unique turbochargers to maximize their efficiency and performance. Unlike diesel engines, H2-ICE engines demand more sophisticated air compression systems to handle their specific energy needs. This has motivated the development of turbochargers designed exclusively for these engines, highlighting the importance of customizing technologies to respond to the particular characteristics of hydrogen as a fuel.

In the realm of sustainable propulsion, hydrogen engines, known as H2-ICE, have emerged as a promising alternative. Unlike diesel engines, these engines require turbochargers specifically designed to handle the peculiarities of hydrogen as a fuel. Throughout this article, we will explore why a specialized approach is necessary for turbochargers in hydrogen engines and how Cummins has led the development of these innovations.

The Specific Demand for Turbochargers for Hydrogen Engines

Hydrogen engines face unique challenges compared to traditional engines, such as diesel. One of the key differences lies in the lower energy density of hydrogen compared to fossil fuels. This means a significantly higher air flow is required to maintain efficient combustion.

The Role of the Turbocharger in H2-ICE

The turbocharger in a hydrogen engine not only compensates for this lower energy density, but also adjusts the air flow precisely to minimize nitrogen oxide (NOx) emissions. Cummins has developed turbochargers such as the CC2 H2 ICE, which uses variable geometry technology to regulate the air flow according to power demand.

Technical Challenges and Innovative Solutions

The adaptation of turbochargers to hydrogen engines requires a series of technical innovations. The demand for greater air flows implies designing larger and more complex turbochargers. However, this can increase costs, which represents a significant barrier to large-scale implementation.

Two-Stage Solutions

One proposed solution is the use of two-stage systems with turbochargers arranged sequentially: a small high-pressure turbo for quick responses at low speeds, and a larger low-pressure turbo for consistent power at higher regimes. This solution is more expensive, but effective in meeting the specific needs of H2-ICE engines.

The Future of H2-ICE Technology

In 2023, Cummins presented a hydrogen combustion engine prototype for a Peterbilt truck, marking the beginning of a new era in automotive technology. This significant step demonstrates a strong commitment towards a greener future, aiming not only at Europe but potentially also encompassing the US market.

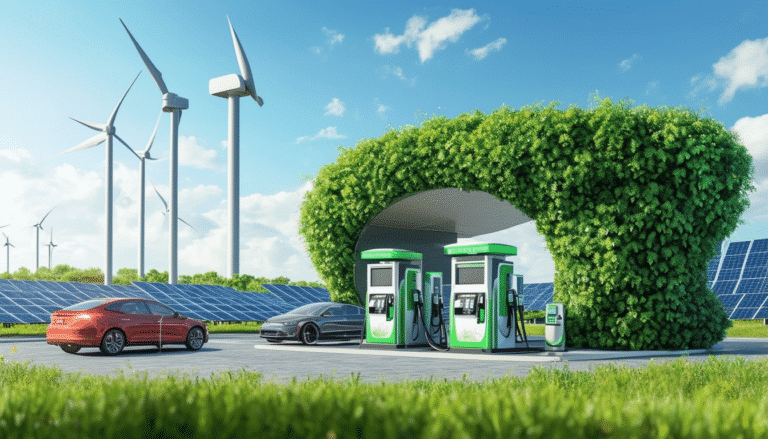

Commercial Implications and Sustainability

The advancement in turbochargers specifically designed for hydrogen engines could transform the transportation industry, especially in sectors like heavy-duty trucks. These engines represent a solid bridge towards a more environmentally friendly automotive future, offering a viable alternative to total electrification.

For those interested in prolonging the life of their engines, even for a minute, here is a practical tip. In the automotive world, history has been rich and varied, as demonstrated by Volkswagen’s V10 TDI engine, famous for its complexity.

For car enthusiasts, there is a limited period to enjoy Porsche’s iconic atmospheric engines. Meanwhile, those seeking cost-effective diesel engines can still consider certain investment options. To dispel common myths about diesel engines, it is recommended to explore this reality.

The Importance of Turbochargers in Hydrogen Engines

The development of specific turbochargers for hydrogen engines is crucial to unlocking their full potential and overcoming the inherent limitations of this type of technology. Unlike conventional diesel engines, hydrogen combustion engines require greater air flow due to the lower energy density of hydrogen compared to fossil fuels. This makes turbochargers not only desirable but imperative to ensure optimal efficiency and performance.

In the case of H2-ICE engines, the implementation of variable geometry turbochargers is fundamental. These devices allow the regulation of air flow according to power demand, which is vital for minimizing nitrogen oxide (NOx) emissions that, while reduced compared to diesel engines, are still present. Precise control of the turbocharger helps generate a cleaner combustion process and reduces turbo lag, thus contributing to improved environmental performance.

With a growing demand for sustainable transport solutions, the refinement of turbocharging systems for hydrogen engines becomes a strategic advance. Manufacturers like Cummins are at the forefront of this innovation, developing larger and more complex turbo systems necessary to meet these unique air flow needs. These efforts focus particularly on markets like Europe, where regulatory pressure points towards more eco-friendly mobility.

The adoption of suitable turbochargers in H2-ICE engines plays, therefore, a decisive role in their ability to be a solid bridge towards a cleaner and more efficient automotive future. By overcoming technical challenges with innovative solutions, the path is paved for a more extensive integration of hydrogen engines into the transportation industry, thus expanding the reach of sustainable propulsion.